You might be tired of your heating and cooling system’s inefficiency or just want to increase your knowledge regarding important HVAC components. Either case, we are here today to answer your question, i.e., what is VFD in HVAC? So that you can understand how this little integration boosts the working potential of your HVAC unit.

Consequently, VFD stands for Variable Frequency Drive (VFD) and is a motor controller that controls the speed and torque of an electric motor. It does this by adjusting the frequency and voltage supplied to the motor and changing its rotational speed.

However, to find profound insights regarding the magical VFD system, let’s dig in a little more and reveal the ultimate secret!

Variable Frequency Driver (VFD): A Comprehensive Guide

A Variable Frequency Driver (VFD) is an electro-mechanical device that controls the speed of rotations of an electric motor by managing its Alternating Current (AC) supply. It varies the frequencies and voltage of the power supply in response to the overall motors’ current load.

Also known as AFDs ( Adjustable Frequency Drivers), ASDs (Adjustable Speed Drivers), VSDs ( Variable Speed Drivers), ACD (Alternating Current Drivers), micro drivers, and inverter drivers, VFDs work on the principle of controlling the motor and boosting the systems’ efficiency and functionality ratio.

Common VFDs Application:

- Alternating Current motors

- Electro-mechanical pumps

- Air volume systems

- Elevators

- Agitators

- Cooling towers

- Heating systems

- Force Draught fans

- Conveyor systems

- Injection molding machines

- Rollers and blowers

- Wire drawing machines

- Furnace fans of drying machines

- Weighing and packing machines

- HVAC systems

VFDs in HVAC System: Major Considerations

The commercial or domestic sector HVAC systems are designed to operate effectively at the peak power supply level. However, the power supply is not constant all the time.

And this low-power or fluctuating supply damages the motors and other components of the HVAC system and affects the HVAC system’s efficiency and functionality.

And this is precisely where Variable Frequency Drivers jump in and show their magic!

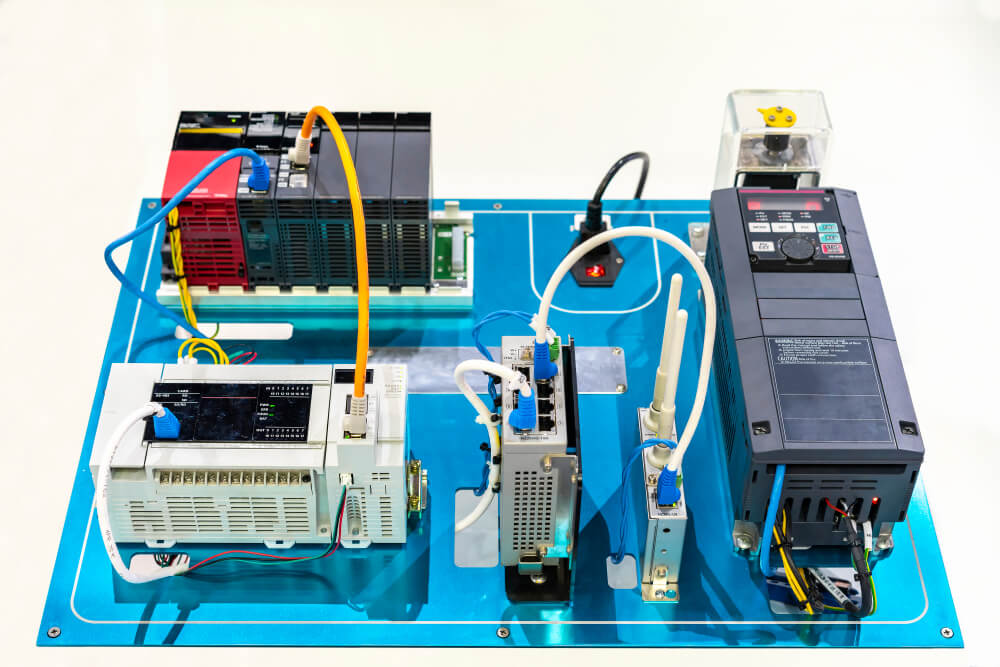

VFDs moderates the motor speed of HVAC systems by converting the Alternating Current (AC) from the circuit into Direct Current (DC) by passing it through the diode bridge rectifier

Then through the filter and finally into the inverting section where its frequencies and voltage are managed and smoothed. From the inverter, the current then passes into the motor with the help of a high-speed bipolar transistor.

The most significant advantage of using a VFD in HVAC systems is that all electronic systems receive an appropriate amount of current supply. However, there’s a hell lot more about VFDs, such as;

Reduction in Energy Bills

Using a VFD in your HVAC system can make your system functional at lower power levels, which can result in a massive reduction in energy bills.

If the VFD reduces the motor rotation speed by 25%, your system’s energy consumption will decrease by up to 60%, according to the studies of Affinity Laws for Centrifugal Pumps and Fans.

And if the motor speed is cut down to 50%, the energy consumption will be 80% to 90% less, which will significantly impact your power bills.

Management of the Extra Demand Charges

Commercial setups like hospitals, offices, industries, and factories have to pay extra demand charges for electricity if they have a large number of HVAC systems, requiring power peaks during particular seasons of the year.

This refers to the extra working of multiple heating systems in winter or Air conditioners only in summer.

However, installing VFDs in HVAC can help the owner reduce these demand charges to a greater extent by managing the power and current supply to the motors.

Prolongs the LifeSpan of Motor and Other Components

As the HVAC systems are considered heavy electro-mechanical machines, they require high-efficiency motors that have worked constantly for years.

But for several reasons, the components of HVAC systems, especially motor systems, start to decrease their working capabilities and deteriorate enough that they either damage the other parts of the system or badly affect its efficiency.

Even if you regularly have maintenance and repair of your system, you cannot simply stop the process of motor deterioration.

However, using a VFD in HVAC systems can slow down the process and prolong your motor and other components’ life.

Boost the Working Capacity of Your HVAC Systems

The starting point of any system’s low efficiency or malfunctioning starts when the system’s power requirements are not fulfilled.

But if you installed a VFD in your HVAC system, it will not only control the overflow or underflow of the current from the circuit but manage its frequency and voltage according to the needs of the motor.

And this will eventually result in increased efficiency of your HVAC system.

Applications of VFDs in HVAC Systems

1. Chilled And Hot Water Systems

Collectively, in the chilled water systems and condensing water systems, including chillers, chilling water pumps, main bypass pipe, chilling fans coils units, and pumping systems, the VFDs are installed at the chilled water pumps and on the fans of cooling towers.

Installing VFDs results in reduced water flow in the pump, which helps lessen the power consumption in the system.

In comparison, the VFDs placed on the cooling tower’s fans are beneficial as it optimizes the fans to maintain the temperature of the condensing water leaving the cooling tower into pipes.

While in the hot water system, the VFDs are installed in both primary and secondary hot water pumps to track the amount of water entering the secondary pump through passing the primary pump from the boiler should be sufficient.

In contrast, the VFD at the secondary water pump manages the supply and regulates water temperature.

2. Air Compressors

Staging control is the factor that manages the on-off and supply of compressed air to the users. If the demand for compressed air increases, multiple compressors will start working simultaneously.

And if the demand increases, the staging control will shut down the compressors. However, the issue is that these continuous on-off cycles of compressors can negatively affect their motor and other components and their efficiency.

So, suppose the VFDs are installed at each compressor. In that case, the flow and supply-demand of the compressed air through the compressors can be effectively handled, resulting in increased working ability and a prolonged life span.

3. Ventilation System

A ventilation system has become a modern-day need of every building, whether a hospital, school, kitchen, or office. It is needed to supply fresh air continuously and exhaust air to keep the balance.

A ventilation system contains an air-handling unit, an air makeup unit, and a fresh-air unit from where fresh air is introduced into the rooms.

The VFD is installed on the air exhaust system, particularly the exhaust fan, to maintain the required building pressure and complete the airflow difference between the demanded and supplied air.

4. Refrigeration System

VFDs are also installed on the compressors, condenser fans, and evaporating fans of refrigeration systems to maintain power and energy flow through the HVAC system. It slows down the speed of the motor and provides variable frequencies and voltages necessary to maintain a uniform temperature.

FAQs: Your VFD Concerns

What IS VFD Full Form In HVAC?

VFD is an abbreviation of Variable Frequency Drivers. It is an electro-mechanical device used to control the voltage and frequencies of Alternating Current (AC) coming from the circuit and change into Direct Current (DC) and supply it to the motor.

What Is The Use Of VFD In HVAC Systems?

The VFD HVAC control system is a new and highly advantageous trend in the electrical, or specifically the HVAC industry. It maintains the energy supply to the motor, fulfills its power requirements, prolongs its life span, and saves it from fast deterioration.

Is Using VFD HVAC Compressor A Good Option?

Yes, absolutely. If your HVAC system’s compressors have VFD installed, then your system’s efficiency will not only boost, but your compressor’s life span will also be prolonged. Having a VFD installed in HVAC is quite beneficial.

Final Thoughts

The positive aspects of using a VFD HVAC controller in your home, hospital, office, school, restaurant, mall, and all kinds of buildings are limitless.

From controlling the current flow to reducing the power bills, one couldn’t enlist all of the advantages of it.

However, the loud noise produced by the VFD in an HVAC system can be a disturbing factor, but there are many practices to reduce them also.

And undoubtedly, the benefits you get from having a VFD in HVAC are much more than bearing the noise.

We hope this article has cleared all your queries regarding the VFD HVAC controller and its impact. If you still have any queries, drop them down in the comment section, and our experts will answer them!