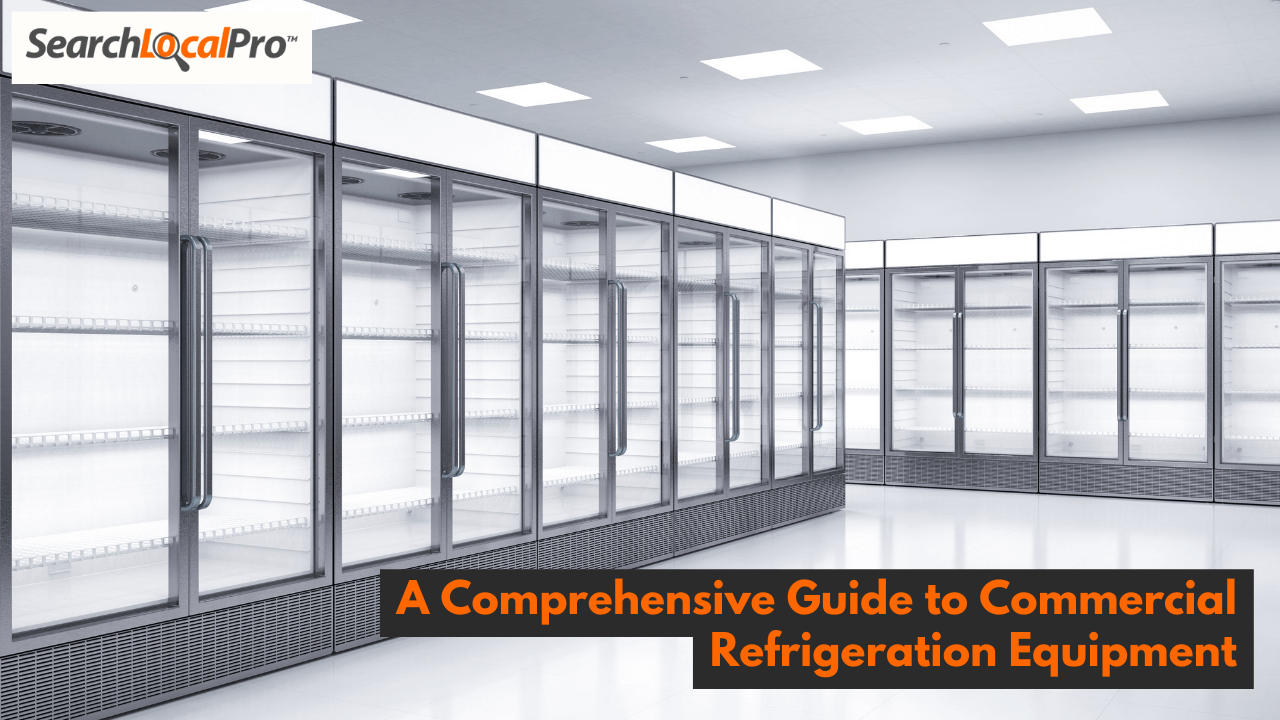

Commercial refrigeration equipment forms the backbone of countless industries, ensuring the safe and optimal storage of perishables. From the crisp vegetables in your local grocery store to the life-saving vaccines at your pharmacy, this equipment plays a vital role in maintaining freshness, quality, and safety.

This comprehensive guide dives deep into the world of commercial refrigeration equipment, exploring the different types available, their applications, and expert tips for choosing and maintaining the perfect unit for your needs.

What is Commercial Refrigeration Equipment?

Unlike their domestic counterparts, commercial refrigeration equipment is designed for the demanding environment of professional kitchens, restaurants, supermarkets, laboratories, and more. Built with robust materials and powerful compressors, these units can withstand frequent door openings, maintain consistent temperatures over extended periods, and accommodate larger volumes of product.

Commercial refrigeration utilizes the principles of thermodynamics to remove heat from a designated space, creating a cold environment ideal for preserving food and other perishable items.

Types of Commercial Refrigeration: A World of Cooling Options

The diverse world of commercial refrigeration offers a variety of equipment to suit specific needs and applications. Here’s a breakdown of some of the most common types:

Reach-In Refrigerators and Freezers:

These workhorse units are the foundation of many commercial kitchens and food storage facilities. Available in various sizes and configurations, reach-in refrigerators maintain temperatures between 35°F and 41°F (2°C and 5°C), perfect for storing a wide range of ingredients, beverages, and prepped foods. Reach-in freezers, on the other hand, operate at sub-zero temperatures, typically ranging from -10°F to 0°F (-23°C to -18°C), ideal for storing frozen foods and ingredients.

Specialized Refrigeration Systems:

Beyond the basic reach-in options, commercial refrigeration offers a variety of specialized systems for unique applications:

- Ammonia Refrigerators: These large-scale industrial units utilize ammonia as a refrigerant, making them suitable for high-volume applications. However, due to safety considerations, their installation and maintenance require specialized expertise.

- Blast Freezers: As the name suggests, blast freezers rapidly freeze large quantities of food at incredibly low temperatures (often reaching -40°F or below, -40°C). This rapid freezing process helps preserve food quality and texture.

- Chillers: These versatile systems don’t directly store food but rather cool liquids like water, glycol, or brine. The chilled liquid is then circulated through other equipment, such as walk-in coolers or display cases, to maintain desired temperatures.

Merchandising Marvels:

Commercial refrigeration goes beyond simple storage, playing a crucial role in product display and customer appeal. Here are some key players:

- Merchandising Refrigerators: These glass-door units showcase chilled beverages, pre-made meals, and other grab-and-go items, allowing customers to browse and select products conveniently.

- Open Air Merchandisers and Accessories: These open-air display cases are ideal for promoting impulse purchases of chilled produce, dairy products, and pre-packaged items. They often come with accessories like misting systems to maintain product freshness.

Undercounter and Worktop Refrigeration

For maximizing space utilization, undercounter and worktop refrigerators and freezers provide convenient options. These compact units are ideal for storing smaller quantities of ingredients or keeping prepared foods chilled within easy reach in kitchens and bar areas.

Prep Refrigerators

Prep refrigerators are designed specifically for the fast-paced environment of a professional kitchen. Often featuring a stainless-steel construction and deep worktops, they provide ample space for storing prepped ingredients, condiments, and grab-and-go items readily accessible to chefs.

Merchandising Freezers

Similar to merchandising refrigerators, merchandising freezers utilize glass doors to showcase frozen food items like ice cream, frozen meals, and vegetables. They come in various sizes and configurations to suit the needs of different retail environments.

Refrigerated Display Cases

Refrigerated display cases are the stars of the show in butcher shops, delis, and bakery displays. These units maintain optimal temperatures while showcasing meats, cheeses, pastries, and other visually appealing products, enticing customers to make a purchase.

Walk-In Refrigerators and Freezers

For bulk storage requirements, walk-in refrigerators and freezers are the go-to options. These large, walk-in rooms maintain consistent cold temperatures for storing significant quantities of food, beverages, and other perishables.

Bar Refrigeration

The world of beverage service has its own set of refrigeration needs. Bar refrigerators and freezers are specifically designed to store and dispense beverages efficiently.

Evaporators:

Evaporators are a critical component within any commercial refrigeration system. They act as the heat exchangers, absorbing heat from the storage area and transferring it to the refrigerant. There are various evaporator types, each suited to specific applications:

- Finned-tube evaporators: These are the most common type, featuring coils with fins that maximize surface area for efficient heat transfer.

- Plate evaporators: Ideal for walk-in coolers and freezers, plate evaporators consist of flat metal plates that provide a large surface area for even heat distribution.

- Air-curtain evaporators: Often found in display cases and open merchandising units, air-curtain evaporators create a cold air barrier to minimize cold air loss when doors are opened frequently.

Commercial Ice Cream Freezers:

Maintaining the perfect scoop-scoop consistency for ice cream requires specialized storage. Commercial ice cream freezers operate at temperatures ranging from -10°F to -20°F (-23°C to -29°C) to ensure ice cream remains firm and flavorful. They come in various configurations, including dipping cabinets, batch freezers, and hardening cabinets, each catering to specific ice cream production and storage needs.

Pass-Through and Roll-In Refrigeration

For seamless workflow and temperature control in busy kitchens, pass-through and roll-in refrigerators and freezers offer a convenient solution. Pass-through units allow for transferring food items between prep areas and service areas without compromising temperature. Roll-in options, on the other hand, provide easy access to large quantities of stored food through roll-in shelves or drawers.

FAQs: Frequently Asked Questions About Commercial Refrigeration

1. What factors should I consider when choosing commercial refrigeration equipment?

Several factors influence the selection of commercial refrigeration equipment, including:

- Type of product being stored: Different products require specific temperature ranges for optimal preservation.

- Storage capacity: Consider the volume of product you need to store.

- Space constraints: Measure your available space to ensure the chosen unit fits comfortably.

- Frequency of access: High-traffic areas might benefit from units with self-closing doors or automatic defrost features.

- Energy efficiency: Look for units with Energy Star certification to minimize energy consumption and operating costs.

2. How can I maintain my commercial refrigeration equipment for optimal performance?

Regular maintenance is crucial for ensuring the longevity and efficiency of your commercial refrigeration equipment. Here are some key tips:

- Cleaning: Regularly clean the interior and exterior of your unit to prevent bacteria growth and maintain airflow.

- Defrosting: Follow the manufacturer’s recommendations for defrosting schedules to prevent ice buildup that can impact performance.

- Coil cleaning: Clean condenser coils regularly to ensure proper heat dissipation.

- Gasket inspection: Check door gaskets for wear and tear and replace them promptly to maintain proper temperature control.

- Scheduled maintenance: Schedule regular preventive maintenance checks with a qualified technician to identify and address potential issues before they escalate.

3. Where can I find reliable resources for servicing my commercial refrigeration equipment?

Most commercial refrigeration equipment manufacturers offer recommended service providers. Additionally, online resources and industry directories can help you locate qualified technicians in your area.

Conclusion:

The world of commercial refrigeration offers a diverse range of equipment to cater to any business’s specific needs. By understanding the different types, their applications, and essential maintenance practices, you can ensure your perishables are stored safely and efficiently, maximizing their shelf life and minimizing spoilage. With the right equipment and proper care, commercial refrigeration systems become silent partners in your success, keeping your operation running smoothly and your customers satisfied.